Explain two (2) types of solid ground floor construction for domestic building.

(25 marks, 2017 Q3)

A.

A ground-level floor can be an earthen floor made of soil, or be solid ground floors made of concrete slab.

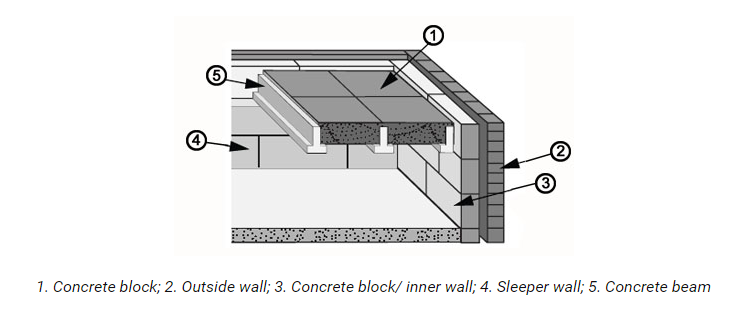

1) Suspended Slab Floor

You can see beam and block flooring here.

2. Solid ground floor.

Ground level slab floors are uncommon in northern latitudes where freezing provides significant structural problems, except in heated interior spaces such as basements or for outdoor unheated structures such as a gazebo or shed where unitary temperatures are not creating pockets of troublesome meltwaters.

Ground Preparation

- Before the ground floor can be constructed, the ground must be prepared to ensure the slab has consistent support.

- Topsoil and any vegetable matter must be removed from the site. It is easily compressed and may sink causing the slab to settle and crack up.

- Pre-existing foundations must be appropriately dealt with.

- Precautions must be taken against ground contaminates, gases, landfill gases, radon, vapours etc.

- Avoid constructing ground bearing slabs on clay in summer and autumn unless NHBC is satisfied that the soil is not desiccated.

- Solid floors can also suffer from sulphate attack where they arch and bulge due to chemical reactions in the hardcore expanding the concrete.

Hardcore

- If the fill depth exceeds 600mm a suspended floor will be required.

- To provide suitable material for the floor slab a layer of clean hardcore at least 150mm thick but no more than 600mm is provided over the prepared oversite ground.

- The fill material used to make up the hardcore should contain nothing larger than about 100mm and be well graded inert fill without hazardous materials. It should contain a range of particles so that it can be firmly compacted such as clean broken bricks, roof tiles, concrete or crushed stone or ready-made loose granular material such as ‘type 1’ hardcore can be used.

- Fill should be mechanically compacted using a small vibrating plate or roller in layers no thicker than 225mm so that no air pockets are present and settlement is avoided.

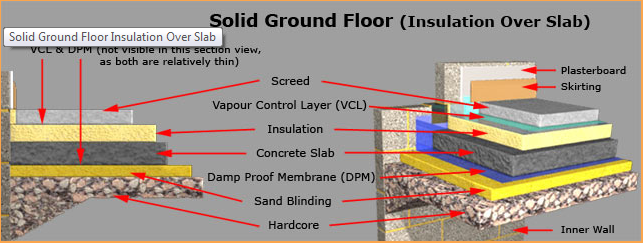

- A layer of a minimum 20mm but can be up to 50mm of sand blinding should be provided over the hardcore before laying the concrete or DPM and will be essential to prevent sharp stones from puncturing the sheet DPM.

Damp Proof Membrane

- To prevent dampness getting through a ground bearing concrete floor should be protected by an impervious layer, usually a 1200 gauge (0.3mm) heavy duty polythene damp-proof membrane.

- The DPM can be positioned either on the sand blinding or on the concrete slab.

- Joints in a Polythene DPM should be welted or taped and should overlap by at least 300mm.

- The DPM must be linked with the DPC in the walls, to ensure that the entire interior of the building is protected from moisture by a continuous, impervious barrier.

- The DPM will need to be dressed up around service entry points.

Ref:

http://www.buildingregs4plans.co.uk/foundation_floor_wall_3d_detail.php

Further reading here on old building flooring where there was no slab, ie. lime floor, earth floor or limecrete floor.