Q.

(a) Explain the factors that influence the choice of steel and concrete as material for framed structures. (15 marks)

(b) Outline the advantages of the following frame structures:

(i) in-situ cast reinforced concrete structures

(ii) steel frame structures (10 marks)

(25 marks, 2016 Q2)

A.

Part 1 also asked about framed structure:

a) Factors that influence choice of steel and concrete as material for framed structures are:

- Cost - where steel now costs more than reinforced concrete

- Speed and efficiency of construction - steel is better

- Availability of material - concrete is easily sourced

- Skill of labour, higher skill required by workers in assemble of steel structures

- Resistance to corrosion and fire - where steel is vulnerable, concrete is resistant

- Flexibility - steel is flexible, can be bent without cracking. Better during earthquake.

- Aesthetic value - steel can be made into various uniformed shape and assemble at site.

b)

i) in-situ cast reinforced concrete structures

Advantages are:

1- Low Cost (Than Steel Structures)

2- Good Safety (Compared to its Price)

3- High Compressive Strength (Best choice for lower earthquake zones)

4- Material Availability (Than Steel Structures)

5- Wide Worker Availability & Easy Workmanship/Operation

6- Easy Maintenance & Lower Maintenance Cost

7- Better resistance against fire

Disadvantages are listed here.

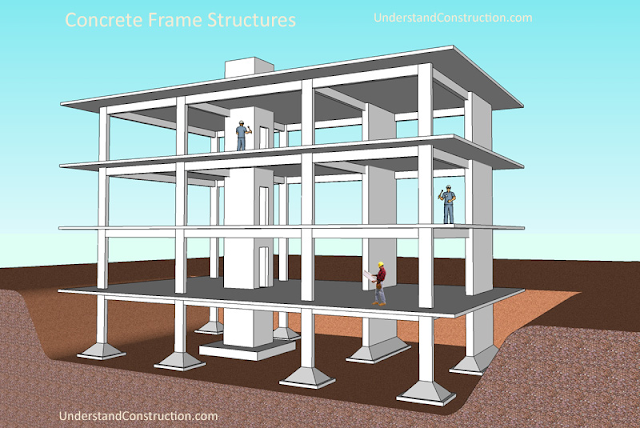

Concrete Frame Structure

Concrete frame structures are a very common - or perhaps the most common- type of modern building internationally. As the name suggests, this type of building consists of a frame or skeleton of concrete. Horizontal members of this frame are called beams, and vertical members are called columns.

Humans walk on flat planes of concrete called slabs (see figure 2 at the bottom of the page for an illustration of each of the major parts of a frame structure). Of these, the column is the most important, as it is the primary load-carrying element of the building . If you damage a beam or slab in a building, this will affect only one floor, but damage to a column could bring down the entire building.

Some other important components of concrete frame structures are:

Shear Walls are important structural elements in high-rise buildings. Shear walls are essentially very large columns - they could easily measure 400mm thick by 3m long - making them appear like walls rather than columns. Their function in a building is to help take care of horizontal forces on buildings like wind and earthquake loads. Normally, buildings are subject to vertical loads - gravity. Shear walls also carry vertical loads. It is important to understand that they only work for horizontal loads in one direction - the axis of the long dimension of the wall. These are usually not required in low-rise structures.

Concrete frame would be more complete as of walls. Compared to steel frame building where it still requires some type of wall - made of concrete, bricks or glass, concrete frame building can make used of shear walls as the walls.

ii) Steel frame structure.

Steel Frame Structure

Advantages are:

Steel construction is most often used in

- High rise buildings because of its strength, low weight, and speed of construction

- Industrial buildings because of its ability to create large span spaces at low cost

- Warehouse buildings for the same reason

- Residential buildings in a technique called light gauge steel construction

- Temporary Structures as these are quick to set up and remove

Speed and efficiency

- Computer modelling before fabrication on computer numerically controlled (CNC) equipment means the components are produced right first time and there is minimal rework

- Earlier construction provides faster completion and payback commencement

- Faster construction means the builder’s staff can be released earlier to start the next project

- Steel is a structurally efficient building material and so buildings are lighter and often foundations can be smaller as a result

- Steel is fabricated in controlled conditions driven by 3D modelling and CNC equipment increasing safety and reducing MTIs and LTIs

- A test certificate is available for all steel used and this can be made traceable through to the finished product

- Design for standardised bolted connections and repetitive floor plates can increase speed of construction

Reducing onsite risks

- Steel use reduces the number of workers on site (approximately 10 to 20 per cent of the labour needed for concrete construction), reducing accident liability for builders

- Pre-assembled steel packages can be lifted straight from the truck in sequence

- Off site fabrication relieves congested and hard to access sites

- Reduced noise and dust and construction times ease disruption to current occupants and neighbourhoods

- For domestic housing, steel framing, roofing and cladding offer more termite-free and fire resistant abodes than with other commonly used building materials

Sustainability and waste reduction

- Waste removal is significantly less than for a concrete building

- More than 95 per cent of all structural steel is recovered and reused or recycled

- Steel buildings inherently lend themselves to structural addition and modification easily

- Independently certified steel fabricator members of the ASI’s Environmental Sustainability Charter attract an extra Green Star point for projects

- Savings in freight and materials through not having to use and remove temporary formwork

- The design can be future proofed for longer life such as provision of large beam penetrations to accommodate future services

That is why steel is used from frame building since 18th century.

Steel

“Steelwork in major construction is on the rise as builders become more attuned to the advantages of using the material in easing onsite risks, speeding development for earlier returns and environmental benefits,” said Alan Marshall, communications manager at the Australian Steel Institute.

The US-based Council on Tall Buildings and Urban Habitat recently reported the number of composite multi-level projects over 200 metres that typically comprise a steel frame with metal decking, rose 54 per cent worldwide in 2014.

“Australia has experienced a similar resurgence,” said Marshall. “This is particularly the case along the eastern seaboard where, during the same period, about 20 composite multi-level projects are underway, such as at 480 Queen Street, which is the first steel framed building of its size in Brisbane. It utilises a parallel beam flooring system to achieve five-day floor cycle times, along with many other benefits gained from composite design and build programs.”

480 Queen Street, Brisbane

Marshall argues the case for steel under three key criteria: speed and efficiency; the reduction of on-site risks; and sustainability and waste reduction.

Ref: