Q.

a) Explain the importance of natural ventilation in a building and the effects of such ventilation. (7 marks)

b) Explain mechanical ventilation and the types of systems available and what are the requirements by the local authority with regards to fresh air supply in a building. (18 marks)

(25 marks, 2011 Q6)

A.

(a)

Read "Concepts and types of ventilation" by WHO hosted at NCBI here.

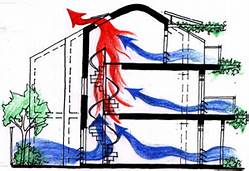

Natural ventilation is the process of supplying air to and removing air from an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure differences arising from natural forces.

With an increased awareness of the cost and environmental impacts of energy use, natural ventilation has become an increasingly attractive method for reducing energy use and cost and for providing acceptable indoor environmental quality and maintaining a healthy, comfortable, and productive indoor climate rather than the more prevailing approach of using mechanical ventilation. In favorable climates and buildings types, natural ventilation can be used as an alternative to air-conditioning plants, saving 10%-30% of total energy consumption.

Natural ventilation systems rely on pressure differences to move fresh air through buildings. Pressure differences can be caused by wind or the buoyancy effect created by temperature differences or differences in humidity. In either case, the amount of ventilation will depend critically on the size and placement of openings in the building.

Ref:

Natural ventilation. Wikipedia, available at

https://en.wikipedia.org/wiki/Natural_ventilation

Andy Walker, 2014. Natural Ventilation. National Renewable Energy Laboratory. Available at

https://www.wbdg.org/resources/naturalventilation.php

(b) Mechanical ventilation (not mechanical (or artificial) ventilation for emergency medicine!)

Ventilation (architecture) is the intentional introduction of outside air into a space.[1] Ventilation is mainly used to control indoor air quality by diluting and displacing indoor pollutants; it can also be used for purposes of thermal comfort or dehumidification when the introduction of outside air will help to achieve desired indoor psychrometric conditions.

The intentional introduction of outside air can be categorized as either mechanical ventilation, or natural ventilation.[2] Mechanical ventilation uses fans to drive the flow of outside air into a building. This may be accomplished by pressurization (in the case of positively pressurized buildings), or by depressurization (in the case of exhaust ventilation systems).

Mixed mode ventilation systems use both mechanical and natural processes. The mechanical and natural components may be used in conjunction with each other or separately at different times of day or season of the year.[3] Since the natural component can be affected by unpredictable environmental conditions it may not always provide an appropriate amount of ventilation. In this case, mechanical systems may be used to supplement or to regulate the naturally driven flow.

Outdoor air can also enter a building by infiltration - the uncontrolled flow of air from outdoors to indoors through leaks (unplanned openings) in a building envelope. In buildings that make no intentional design for mechanical or natural ventilation, circumstantial infiltration has been referred to as adventitious ventilation.[4] In exhaust ventilated buildings, the intended flow of outside air may enter through planned inlets, but it will also enter through unplanned leaks in the building envelope. Generally, all outside air that crosses the building envelope through leaks is referred to as infiltration, whether it is driven by mechanical systems or natural mechanisms like wind.

In many instances, ventilation for indoor air quality is simultaneously beneficial for the control of thermal comfort. At these times, it can be useful to increase the rate of ventilation beyond the minimum required for indoor air quality. Two examples include air-side economizer strategies and ventilation pre-cooling. In other instances, ventilation for indoor air quality contributes to the need for - and energy use by - mechanical heating and cooling equipment. It hot and humid climates dehumidification of ventilation air can be a particularly energy intensive process.

In many scenarios, heat recovery ventilation can reduce energy use for heating and cooling by facilitating sensible heat exchange between exhaust air and incoming ventilation air. Energy recovery ventilation transfers moisture in addition to sensible heat. However, heat recovery can increase the fan power required for ventilation, and may increase energy use for heating and cooling for periods when ventilation would be beneficial for the control of indoor thermal comfort.[5]

The design of buildings that promote occupant health and well being requires clear understanding of the ways that ventilation airflow interacts with, dilutes, displaces or introduces pollutants within the occupied space. Although ventilation is an integral component to maintaining good indoor air quality, it may not be satisfactory alone.[6] In scenarios where outdoor pollution would deteriorate indoor air quality, other treatment devices such as filtration may also be necessary. In kitchen ventilation systems, or for laboratory fume hoods, the design of effective effluent capture can be more important than the bulk amount of ventilation in a space.

More generally, the way that an air distribution system causes ventilation to flow into and out of a space impacts the ability for a particular ventilation rate to remove internally generated pollutants. The ability for a system to remove pollution is described as its "ventilation effectiveness". However, the overall impacts of ventilation on indoor air quality can depend on more complex factors such as the sources of pollution, and the ways that activities and airflow interact to affect occupant exposure.

Ventilation should not be confused with air motion induced by ceiling fans or other devices. Air motion influences thermal comfort, it can decrease thermal stratification, and it may cause pollutant dilution by way of mixing, but it does not introduce outside air and therefore does not classify as ventilation.

Ventilation should be considered for its relationship to "venting" for appliances and combustion equipment such as water heaters, furnaces, boilers, and wood stoves. Most importantly, the design of building ventilation must be careful to avoid the backdraft of combustion products from "naturally vented" appliances into the occupied space. This issue is of greater importance in new buildings with more air tight envelopes. To avoid the hazard, many modern combustion appliances utilize "direct venting" which draws combustion air directly from outdoors, instead of from the indoor environment.

Types of mechanical ventilation

Importance of Ventilation

Ventilation in a structure is important to remove water vapour formed by respiration, burning and cooking. It is required for removing odours, e.g., from a toilet or kitchen. If water vapour is permitted to accumulate, it may damage the structure, insulation or finishing. It is reported that improper ventilation is the cause of about half of all indoor air quality problems in your work place.

Ventilation is becoming a point of major concern for industrial workplaces and factories due to the fumes, gases, vapours and heat generated. In natural ventilation, air moves through opened windows and doors. Air movement associated with infiltration and natural ventilation is caused by air temperature differences between indoors and outdoors and by wind.

Equipments to Handle Ventilation

There are a number of mechanical devices that help steady ventilation. Generally exhaust fans are used to remove air from rooms, such as bathrooms and kitchens. There are air handling systems that use fans and duct to continuously remove indoor air and distribute filtered and conditioned outdoor air to strategic points throughout the work place. When there is little infiltration, natural ventilation, or mechanical ventilation, the air exchange rate will be low and pollutant levels will increase.

But most heating and cooling systems, including forced air heating systems do not mechanically bring fresh air inside. Opening windows and doors, operating window or attic fans, when the weather permits, or running a window air-conditioner with the vent control open increases the ventilation rate. Local bathroom or kitchen fans that exhaust outdoors remove contaminants, including moisture, directly from the room where the fan is located and also increase the outdoor air ventilation rate.

Ideal work places should have some kind of mechanical ventilation to remove pollutants. Whether a mechanical ventilation systemd makes sense in your existing homes depends on the house, your existing heating, ventilation and air circulating systems.

Turbo Ventilators

Turbo Ventilators are mechanical devices to handle continuous air-flow. Generally it operates utilizing energy of the wind to induce airflow by centrifugal force. The centrifugal force created to pull up the fresh air in the turbines towards the spinning vanes and out of the turbine. The airfoil vanes pick the wind at the windward side creating continuous airflow increasing proper ventilation.

The wind driven turbo ventilators are used in developed countries because its initial capital cost is very low. These turbo ventilators have adaptability, high capacity per vent. They are more reliable than any other ventilation system. The Turbo Ventilator is designed to withstand a high wind velocity in different weather conditions. It is made of stainless steel or aluminium, therefore virtually maintenance free for more than ten to fifteen years.

Turbo Ventilators operate on wind energy thereby enabling substantial saving in electrical energy to the user. It makes use of a renewable source of energy, i.e wind energy. Since these ventilators are maintenance free for more than ten years they are cost effective also.

Turbo Ventilators help healthy living, reduction in maintenance of plant & machinery, using renewable source of wind energy. In the long run they increase productivity and life of roofing sheets.

As a general rule, hot or stale air will not exhaust through an opening into which wind is blowing. Therefore, regular static ventilators are often found useless. They allow outside wind to enter in the shed because of poor design or location on the roof. They cannot be expected to exhaust.

An efficient means of extracting warm and stale air is through roof mounted turbo ventilators, which create positive draft. Adequate low level provision for the entry of fresh air at normal temperature and pressure should be provided. Well designed turbines ventilators exhaust hot and stale air. They also help providing continuous air flow resulting in effective air changes per hour for the building.

While the electric, powered ventilators work on electricity high running cost on power is required while the wind turbo ventilator costs zero running costs. Moreover, since the turbo wind ventilators are installed in rooftop, it ensures uniform ventilation.

Keep Your Work Place Healthy by Proper Ventilation. MGS Architecture. Available at,

http://www.mgsarchitecture.in/products/rooftop-ventilators/238-keep-your-work-place-healthy-by-proper-ventilation.html