Q.

a) With the aid of diagrams, explain how drinking water is being treated to ensure that it is safe for consumption. (10 marks)

b) With the aid of diagram, explain the indirect hot water system for a two storey building. (15 marks)

(25 marks, 2013 Q2)

A.

(a) Water treatment for safe consumption.

Similar question was asked in 2012 Q4a.

Water treatment is any process that makes water more acceptable for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses including being safely returned to the environment. Water treatment removes contaminants or reduces their concentration so that the water becomes fit for its desired end-use.

Treatment for drinking water production

Treatment for drinking water production involves the removal of contaminants from raw water to produce water that is pure enough for human consumption without any short term or long term risk of any adverse health effect. Substances that are removed during the process of drinking water treatment include suspended solids,bacteria, algae, viruses, fungi, and minerals such as iron and manganese.

The processes involved in removing the contaminants include physical processes such as settling and filtration, chemical processes such as disinfection andcoagulation and biological processes such as slow sand filtration.

Measures taken to ensure water quality not only relate to the treatment of the water, but to its conveyance and distribution after treatment. It is therefore common practice to keep residual disinfectants in the treated water to kill bacteriological contamination during distribution.

World Health Organization (WHO) guidelines are a general set of standards intended to apply where better local standards are not implemeted. More rigorous standards apply across Europe, the USA and in most other developed countries. followed throughout the world for drinking water quality requirements.

Processes

A combination selected from the following processes is used for municipal drinking water treatment worldwide:

- Pre-chlorination for algae control and arresting biological growth

- Aeration along with pre-chlorination for removal of dissolved iron and manganese

- Coagulation for flocculation or slow-sand filtration

- Coagulant aids, also known as polyelectrolytes – to improve coagulation and for thicker floc formation

- Sedimentation for solids separation that is removal of suspended solids trapped in the floc

- Filtration to remove particles from water

- Disinfection for killing bacteria viruses and other pathogens.

Technologies for potable water treatment are well developed, and generalized designs are available that are used by many water utilities (public or private). In addition, a number of private companies provide patented technological solutions. Automation of water and waste-water treatment is common in the developed world. Capital costs, operating costs available quality monitoring technologies, locally available skills typically dictate the level of automation adopted.

Wikipedia search 'Water Treatment', available at

https://en.wikipedia.org/wiki/Water_treatment

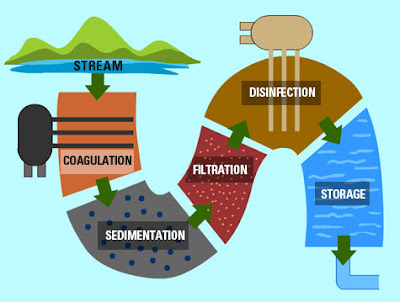

Schematic water treatment process is explained below:

Coagulation stage:

Alum and other chemicals are added to the water at this stage. Suspended particles get stuck to the chemicals to form 'floc'.

Sedimentation Stage:

As particles get stuck they become heavy and sink to the bottom of the chamber. At this stage, most of the particles are stuck to form sediments, sinking to the bottom. The water is passed onto the Filtration chamber.

Filtration stage:

As water passes slowly through this chamber, finer particles (sediments) are filtered out over layers of sand, charcoal and gravel.

Disinfection stage:

Chlorine or other kinds of disinfection methods is applied to kill any bacteria and other living organisms that may be in the water. It is very normal and natural for fresh water to contain living organisms.

Storage stage:

The water is then passed into large storage tanks and left for a while for the action of disinfection to be complete. At the tail end of this storage tanks, huge pipes are connected to transport water to our homes and work places.

How is water treated for use in homes? Available at

(b) Indirect Hot Water System for 2-Storey Building.

This question always come out in past years, as shown in link below.

2011 Q5a

2012 Q4b

2013 Q2b (This question)

2014 Q5a

2015 Q1b

Key:

1,2,4, – Stopcocks used to cut off the water to various parts of the system that are under high pressure.

3 – Draincock – allows the raising main and parts of the system to be drained of water.

5 – Cold water storage tank – situated at the highest part in the building it is controlled with a ball valve which allows the tank to be topped up when water is drawn off.

6, 9 – Gate valves – isolate water supply to parts of the system which are fed under low pressure.

8 – Hot water cylinder

10 – Overflow pipe from storage tank to direct any water outside the building.

11 – Overflow pipe from WC system

12 – Inline valves for isolating a washing machine or dish washer.

The 2 distinctions of Indirect Hot Water Supply System are:

1. The cistren (Storage Tank)

2. Separate Hot Water Piping System

The benefits of indirect hot water supply system are:

Apart from the downstairs kitchen sink tap, and possibly washing machine/dishwasher, water is not supplied directly from the mains to the outlets, instead it is piped to and stored in the cistern in the attic.

Advantages:

Cold-water storage cistern gives an even water pressure which produces quieter plumbing with less wear and tear on fittings. This cold water is stored and always available for use when required. It means the boiler would be supplied with reliable constant pressure water.

Leaks are also less likely on cistern fed systems as it is low pressure and any leak that does occur will be less damaging because less water will escape from the leak. This cold water supply would not damage the boiler.

Pump-boosted power showers can be installed if much raindrop shower is need. If the mains supply is cut off, there is a reserve stored in the cistern to ensure continuous supply of water.

The separate piping installed for the hot water system is dedicated for the heater/boiler. The vent allows the pressure to release itself when it is heated - as water expands when heated. There is less likely the hot water would harden the rubber materials used in the pipes (which is already reduced with copper pipes), especially at the joints or sealants.

Disadvantages:

Noise of cistern filling.

Cistern requires height space to produce pressure - hence boiler might not get water quick enough for consumption if the pipes are small, and pressure is low.

Cistern requires frost protection and maintenance.

More pipe work required. Adequate pipe size to cope with several taps. For carrying heated water, it is to preserve the heat and withstand the heat, not corroded by rusting. Copper pipes are better than iron pipes but they are expensive.

To avoid hygienic issues (with storage of water getting contaminated in the attic with animals and insects dying inside), the only drinking water is in the cold tap over the kitchen sink.

Sources used in the compilation of this answer

http://www.eci.ox.ac.uk/lowercf/pdfdownloads/AppendixM.pdfhttp://www.readersdigest.co.uk/diy/webpages/301b.htm#12

http://www.irish-energy.ie/content/content.asp?section_id=794&language_id=1

Images

http://www.diydoctor.org.uk/projects/Cold%20water%20systems.htm

Indirect water systems interactive quiz http://www.edukate.net/ed_tech.htm

Ref:

Essential Services. Construction Learning Gateway. Available at

http://www.construction-learning-resources.co.uk/page_64.html